ASTM F2381: Standard Test Method for Evaluating Trans-Vinylene Yield in Irradiated Ultra-High Molecular Weight Polyethylene Fabricated Forms Intended for Surgical Implants by Infrared Spectroscopy

Purpose

This test method describes how to quantify trans-vinylene groups in ultra-high molecular weight polyethylene (UHMWPE) components intended for surgical implants using infrared (IR) spectroscopy. The resulting trans-vinylene index (TVI) is used as an internal indicator of radiation dose and crosslinking produced during ionizing radiation treatment (e.g., gamma or electron beam sterilization/crosslinking).

Typical Application

- Orthopedic UHMWPE components (e.g., joint replacement inserts) or test coupons that have been irradiated for crosslinking or sterilization.

- Verification and mapping of radiation dose uniformity and crosslinking through the thickness of a component or preform.

- Supporting process development or quality control where irradiation conditions (source, dose, temperature, oxygen level) are critical.

General Test Description

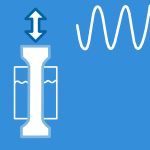

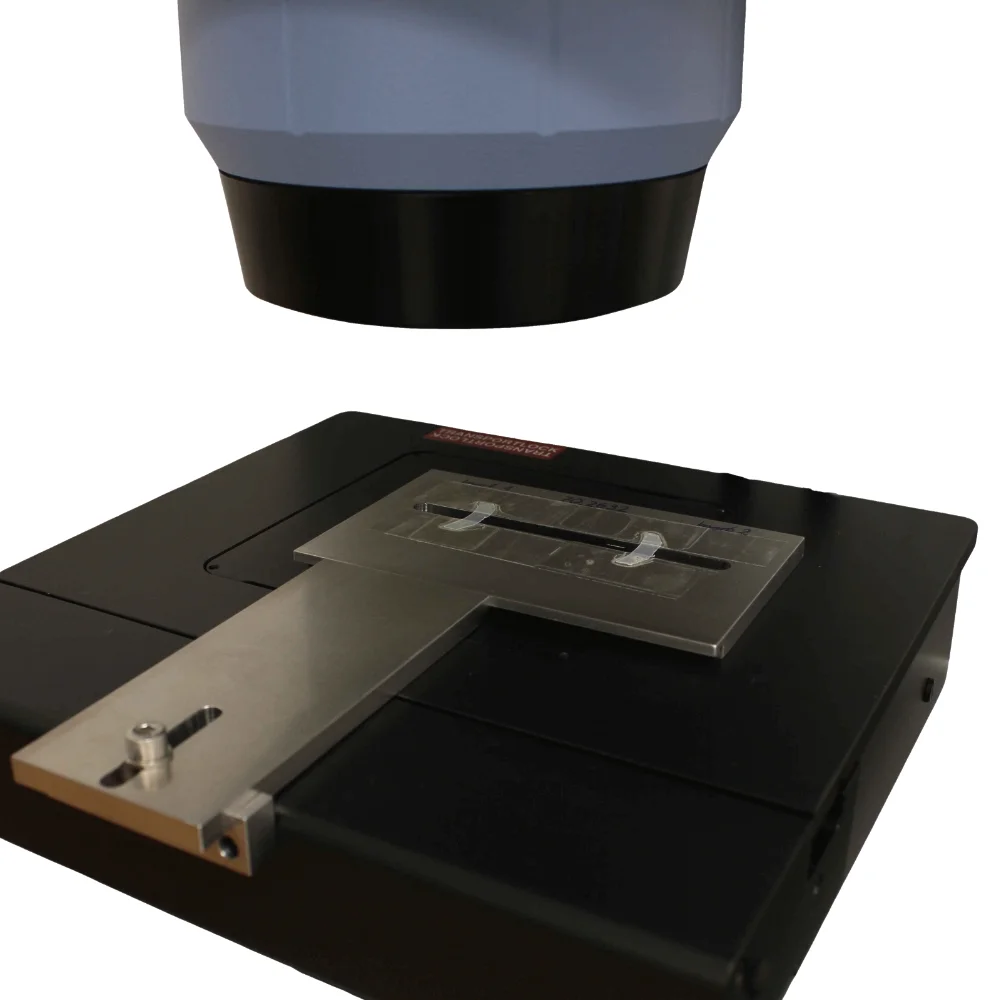

- A thin slice (~200 µm) is cut from the UHMWPE component perpendicular to the articular (or other surface of interest) using a microtome.

- The slice is analyzed in a calibrated FTIR spectrometer. Spectra are collected in small steps (typically matching a ~200 µm aperture) from the surface of interest across the thickness, generating a depth profile.

- For each location, the area of the trans-vinylene absorption peak at ~965 cm-1 is measured and normalized by the area of the CH peak at ~1370 cm-1 to yield the TVI (ratio of peak areas). This normalization compensates for minor variations in the thickness of the specimen slice.

- A “depth locator” (DL) is calculated from aperture size and step size to map each TVI value back to its distance from the articular surface, resulting in a TVI-versus-depth profile.

- Surface roughening of the film is used to reduce Fourier rippling artifacts without changing the true absorption peaks.

What the Test Demonstrates

- Relative level of radiation-induced trans-vinylene unsaturation (and thus crosslinking) at different depths in the UHMWPE.

- Uniformity of received radiation dose and crosslinking within a component or preform, assuming an appropriate calibration curve between TVI and dose has been established for the specific irradiation conditions.

Key Points for Device Developers

- The output is a TVI depth profile, not a direct mechanical property; separate testing is needed for wear or strength.

- Calibration to actual dose is material- and process-specific and requires external dosimetry; F2381 itself does not define target TVI values or “acceptable” ranges.

- Test reports should document resin and lot, consolidation and post-treatments, sample geometry, film preparation, spectrometer setup, and analysis method (manual vs software).