ASTM F1160: Standard Test Method for Shear and Bending Fatigue Testing of Calcium Phosphate and Metallic Medical and Composite Calcium Phosphate/ Metallic Coatings.

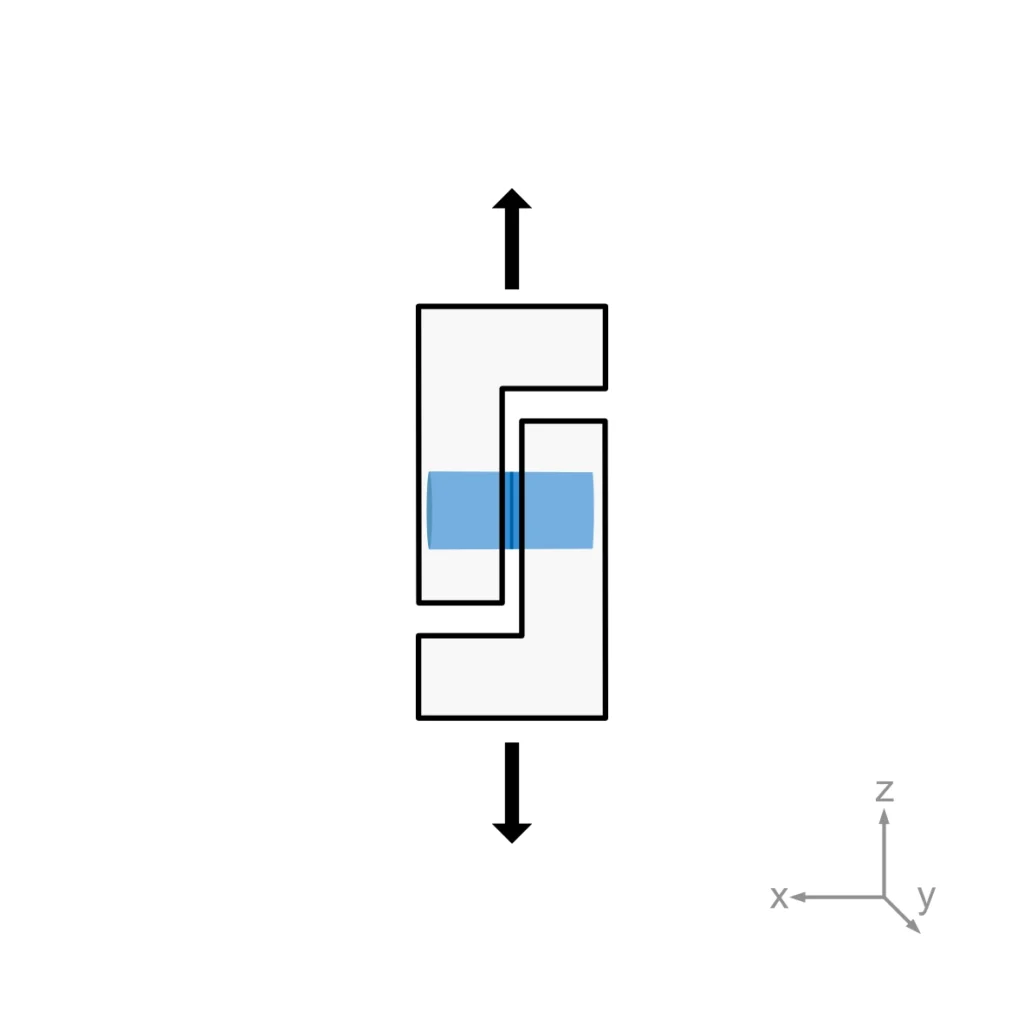

This test method covers the procedure for determining the shear and bending fatigue performance of calcium phosphate coatings and of porous and nonporous metallic coatings and for determining the bending fatigue performance of metallic coatings oversprayed with calcium phosphate. This test method has been established based on plasma-sprayed titanium and plasma-sprayed hydroxylapatite coatings. The efficacy of this test method for other coatings has not been established. In the shear fatigue mode, this test method evaluates the adhesive and cohesive properties of the coating on a metallic substrate. In the bending fatigue mode, this test method evaluates both the adhesion of the coating as well as the effects that the coating may have on the substrate material.

These methods are limited to testing in air at ambient temperature. These test methods are not intended for application in fatigue tests of components or devices; however, the test method which most closely replicates the actual loading configuration is preferred.

The test method corresponds to ASTM F1044 but dynamical load conditions instead of static ones are used.

Calcium-phosphate coatings, porous and non-porous metallic coatings, and metallic coatings oversprayed with CaP (e.g., plasma-sprayed Ti and HA). Additionally, additively manufactured coatings can also be tested.

ASTM F1160 is used to evaluate the shear fatigue strength of additively manufactured porous surface structures designed to promote bone ingrowth on implants. Regulatory bodies typically require fatigue testing of these structures to demonstrate long-term mechanical integrity at the coating–substrate interface.

Results depend on the complete material system (coating/substrate combination), specimen geometry, surface preparation and condition, coating thickness and porosity, applied stress amplitude and spectrum, as well as fixture design and alignment. Because the test is conducted in air, environmental effects such as saline exposure are excluded.

ASTM F1044 is a static shear adhesion test; F1160 is fatigue (shear and bending) test to assess durability and potential substrate effects.

Typical failure modes are adhesive failure of the coating at the coating-substrate interface and cohesive failure within the coating. These are considered valid outcomes, as they reflect the true performance of the coating system. Invalid failure modes include separation of the test adhesive layer (used to bond the specimen to the loading fixture), substrate fracture, or any failure outside the intended coating–substrate interface. Such results do not represent coating adhesion or fatigue performance. To minimize the risk of invalid failure, we perform gluing trials to optimize adhesive selection and sample preparation. With our extensive experience, we can select the appropriate bonding method for your specific coating, ensuring reliable and reproducible testing.

Testing according to ASTM F1160 is required or expected by many regulatory bodies worldwide for coated or porous-surfaced implants. International standards such as ISO 13779-2 (hydroxyapatite coatings) and ISO 13179-1 (plasma-sprayed coatings), as well as the FDA draft guidance “Characterization of Metallic Coatings and/or Calcium Phosphate Coatings on Orthopedic Devices” (01/2024), reference ASTM F1160 as a method to demonstrate coating durability.

If you are planning a submission in a specific region (e.g., FDA, EU, PMDA), ask our experts—we can guide you on the exact test setup and documentation needed for your target authority.