ASTM F2102: Standard Guide for evaluating the Extent of Oxidation in Polyethylene Fabricated Forms Intended for Surgical Implants

ISO 5834-4: Implants for surgery – Ultra-high-molecular-weight polyethylene – Part 4: Oxidation index measurement method

Purpose

ASTM F2102 provides a standardized approach for assessing the relative extent of oxidation in high-density polyethylene and ultra-high-molecular-weight polyethylene used in surgical implants. Oxidation is quantified through infrared spectroscopy, focusing on carbonyl groups that form as the material oxidizes.

ISO 5834-4 is mostly interchangable with ASTM F2102. The only relevant difference is that it specifies a tolerance on the thickness of the specimen slice.

Typical Application

The guide is used for orthopedic implant components such as tibial inserts or hip bearings. It supports comparisons between different samples assuming that the samples have undergone oxidation via the same mechanisms (e.g. shelf aging, accelerated aging).

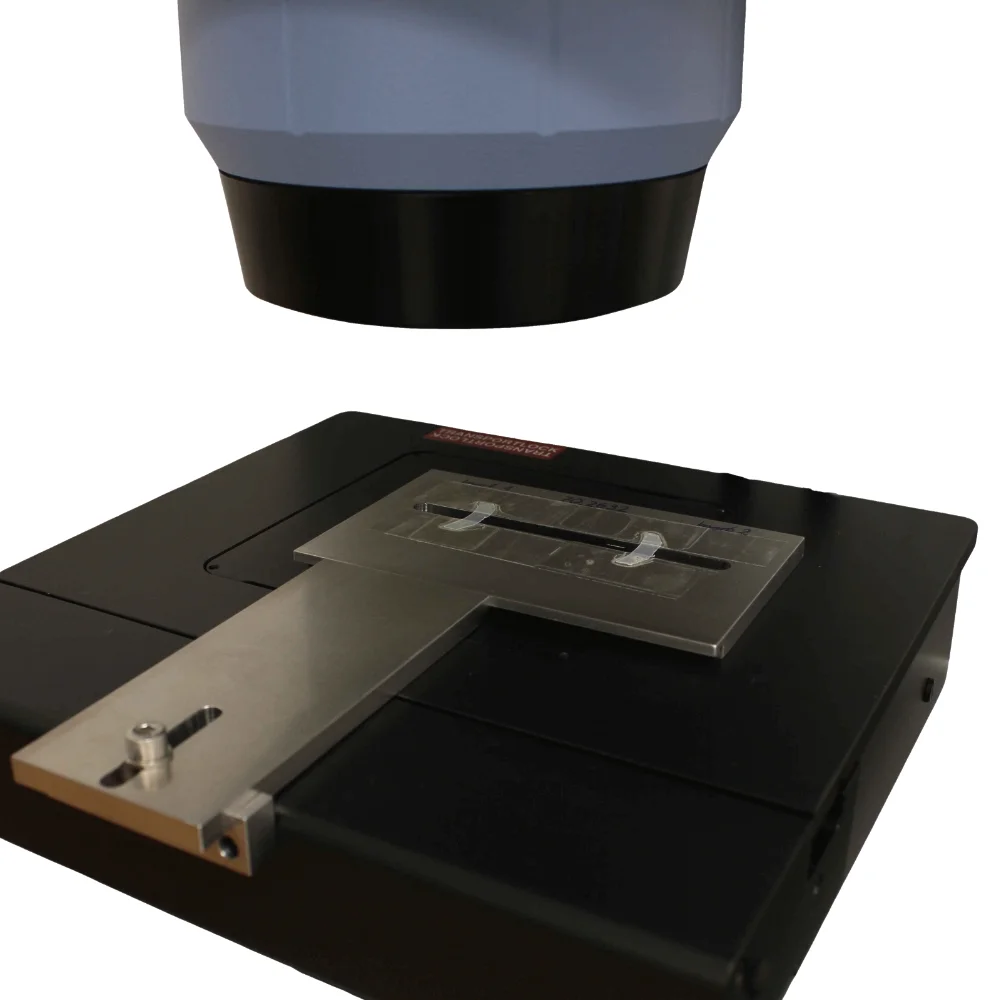

General Test Description

The method relies on Fourier Transform Infrared spectroscopy to measure the area of carbonyl absorptions near 1720 cm⁻¹, normalized to the C–H absorption peak near 1370 cm⁻¹. Thin microtomed slices of about 200 µm are analyzed perpendicular to the surface of interest.

A series of spectra is collected in depth increments that match the spectrometer’s aperture, producing an oxidation index profile over the component’s thickness. Key calculated values include surface oxidation index, bulk oxidation index, and maximum oxidation index. For retrieved components, lipid extraction is required to avoid overlap with lipid absorption peaks.

Key Points

- Quantifies carbonyl-based oxidation via an area-based oxidation index.

- Provides definitions for oxidation index, depth locator, bulk and surface oxidation indices.

- Requires precise FTIR configuration, appropriate baseline handling, and validated scan numbers.

- Lipid extraction (heptane or hexane) is mandatory for retrieved or lipid-exposed samples.